The colliery at Astley Green was founded in 1908 by the Pilkington Colliery Company. Although large amounts of coal lay deep beneath the surface waiting to be dug out, the ground above was not very suitable for mining. It was extremely wet and unstable, perhaps unsurprising as it lies on the edge of the extensive bog land area of Chat Moss. However demand was so high for coal that it was deemed worth extracting. Accordingly, a new technique to sink the first shaft was developed – the Drop Shaft method. This involved creating a hole using iron rings with a sharp cutting edge at the bottom of them. The rings were forced through the ground using thirteen hydraulic jacks.

Head Wrightson of Stockon on Tees built the pit headgear framework. This consisted of a riveted steel lattice construction standing at over 24 metres tall, and the one for Number 1 shaft is still in position today.

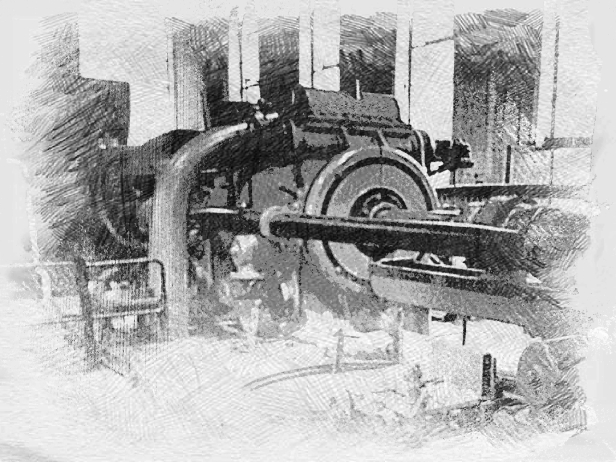

The steam winding engine was built by Yates and Thom of Canal Ironworks, Blackburn. It was housed in a purpose built engine house next to the shaft. The engine was driven by four steam cylinders in a twin compound arrangement. It was connected to a huge bicylindro-conical drum, which in turn was connected to the headgear pulleys. This enabled coal to be wound up and the men with supplies to be lowered down the shaft. At full capacity, the steam engine was able to haul nine tonnes of coal from a depth of 890 yards, every two minutes. Yates and Thom also supplied the boilers for the colliery.

Astley Green opened in 1912, and was centred around two main shafts, Number 1 and Number 2. Each had their own headgears and dedicated winding engines. Extensive railway tracks clustered in the yard nearby to transport the coal away to the main lines. There was a rail link that led south to Astley Junction which connected to the Manchester to Liverpool Line. In 1930, after formation of Manchester Collieries Ltd, a new line was constructed to the Boothstown Basin where it joined the Bridgewater Collieries Network.

The whole complex of Astley Colliery sits very close to the Bridgewater Canal. Coal was loaded into wooden boxes and these were transferred using a steam crane onto barges waiting at the canal side wharf. These would then carry their cargo to the power stations at Trafford Park and Stretford. The colliery also did local deliveries using horse and cart, which was later replaced by a motor lorry.

In 1928, Astley Colliery became part of Manchester Collieries as it was amalgamated with other local pits. In the 1950s it still had a bright future, and was very much seen as a show mine with heads of industry and royalty visiting. However, by the late 1960s production targets were increasingly hard to meet and its days were numbered.

The End of Astley Green’s Mining Operations

On the third of April 1970, the last load of coal was hauled up. Demolition began in the same year. Most of the colliery was knocked down, but pressure was brought to bear by Lancashire Council, local museums and archaeologists to preserve some of the site. Accordingly, the pit headgear for Number 1 shaft, along with its winding engine, internal travelling crane and shed, were left in place. The remnants of the site were then mothballed, but they were not forgotten.

The Site is Restored and the Museum Opened

In 1983, some ten years after demolition of the rest of the site occurred, Red Rose Steam Society took a lease on the site and moved in. The winding engine had been exposed to the elements and was in a poor condition. They managed to secure some grants from Greater Manchester Council to try to restore it. After 25 years of labour the engine was once again in full working order, and in 2013 it ran for the first time in decades. It was now powered using not steam but compressed air. Its four cylinders run in a ‘twin tandem compound arrangement’ to deliver 3300 horsepower at 58 revolutions per minute. It is the largest colliery steam engine of its type in Europe.

Focus has now turned to the restoration of the Number 1 pit Headgear which is on the English Heritage ‘At Risk’ register. Reports show that it is repairable. It is the only one left in Lancashire, and the best example of its kind in Britain. However, a large amount of money must now be raised for repairs and to secure its existence for future generations.

Some of the site’s colliery offices have been converted into a tea room for visitors, and a replica miners cottage named ‘Shaw Yard’ has been constructed. The cobbled street, historic gates and gate post have also been preserved, giving the site a heritage feel. The site also contains a narrow gauge mineral railway line along with trains and trucks used for transporting the coal. This is being developed into a circuit on which visitors will be able to ride on the train.

The museum is owned by Wigan Borough Council but the site is completely run by volunteers from the Red Rose Steam Society, who lease the site. They have ambitious plans to link up with Leigh Spinners Mill which also contains a steam engine, and the new RHS Bridgewater Gardens via the nearby Bridgwater Canal wharf.

There is still much for the volunteers to do. The museum has recently acquired Fred Dibnah’s pit headgear, which he had erected in his back garden. This needs to be reassembled. Other exhibits also await refurbishment, such as the pit cage from Bickershaw Colliery near Leigh. This was used by men to inspect the water pumps at that colliery. Numerous train engines and carriages are also on show, waiting for the circular track to be installed.

The volunteers have also diversified the use of the site. They are developing a nature reserve to increase the wildlife value, and the museum is also used as a key set for the BBC drama Peaky Blinders.

When you visit you will find the volunteers very friendly and welcoming. They are also keen to recruit new members to their cause.

Site visited by A. and S. Bowden, late 2018. This piece written 2020.

Access

Opening Times: Tuesday, Thursday, Saturday and Sunday

Winter times: 1pm-4pm

Summer times: 1pm-5pm

The website is here

Nearby, just a short drive away

The Lost Church of St Stephen’s

The Seven in Lancashire, Cleworth Hall

References

Lancashire Mining Museum Astley Green Masterplan Vision, Randall Thorp January 2019 (the full report can be downloaded from the museums website as a pdf document)

On site interpretation in the engine house

lancashireminingmuseum.org

Comments are closed.